Manufacturing Engineering

|

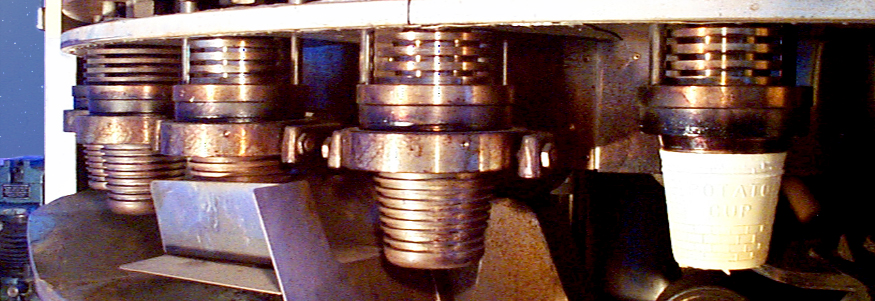

Bayly has been developing its manufacturing engineering capabilities since 2000 with the launch of its Influx Manufacturing Innovation business division. In early 2005, Bayly’s management team decided that Influx Manufacturing Innovation was to be integrated into Bayly as a core capability. Industrial Engineering Bayly’s uses it’s industrial engineering capabilities to assist its clients to find solutions for all types of problems in manufacturing processes and their manufacturing environment. Bayly's problem solving capaibilities involve solving particular problems as part of a program of continuous improvement rather than a total overview of a facility. Bayly brings to our clients a different perspective unfettered by the influence of history, politics and personalities to expose a range of credible options that can be implemented to achieve the desired change. An important part of this different perspective is a wide range of experience in similar and disparate industries in Australia and internationally. Our capabilities are available to our clients to solve bottlenecks, improve yields and reduce cycle times in processing and tooling changeover. Process Improvement Bayly has the capability to not only scope solutions, but to also implement the changes within the client’s facility and organisation. New or modified equipment, installed and set to work, the documentation of changes and the training of staff in the new processes can all be provided by the team at Bayly. Simulation Bayly uses its Arena simulation software to simulate the material flows, process evolutions and line setups and configurations to provide an ongoing model of a production facility or to test different configurations at the design stage. Bayly’s simulation capability is suited to high speed manufacturing and processing lines as well as batch processing situations. These tools allow us to prototype the solutions before implementation and provide an economic basis for decision making. Bayly uses simulation to;

Bayly use Ansys FEA tools to model stress, deflection and dynamic behaviour of systems, sub-systems and their components to ensure the integrity of the design. Visual Nastran is used to model the dynamic behaviour of systems and more specifically mechanisms to ensure that the system loads are representative of the real environment. Moldflow simulation tools are used to model and represent the filling of plastic injection moulding tools. Machine Design With Bayly’s team of mechanical engineers and designers, the design of special purpose machinery is also a key capability. Bayly’s team is often used in the conceptual design of solutions with our clients, but also includes the capability to take a project to provide a complete turnkey solution. Bayly’s team of engineers has extensive experience in the design of automated equipment, in robotic applications and the design of precision machine tools that must consistently produce accurate outcomes at high loads and work rates over extended periods of time. Safety Safety is not an optional consideration in the manufacturing environment in Australia and around most parts of the World. From the design of machines and equipment, safety standards for guarding (AS 4204) to a complete understanding of the various state based regulatory codes, Bayly’s team are focused on ensuring that clients, their employees, suppliers and the public are not exposed to hazards that can be controlled. Bayly’s work practices in this regard are centered around the recognised process that is the basis of best practice; > hazard identification > risk assessment > risk mitigation Bayly’s value to our client is again provided through the wide ranging experience that the team has in applying this practice across different sites and in different situations, and in the knowledge of the outcomes that these solutions provide. Material handling is another area where Bayly’s expertise in human factors engineering and ergonomics provides the best outcomes for our clients in considering the size, weight and shape of loads carried by their workers and the way that their body needs to move to accomplish the handling task. |

Cleaner Production - a better world and money in your pocket

Bayly maintains this capability focused on assisting its clients achieve outcomes in reviewing their manufacturing processes to provide environmental and cost savings or income generating benefits. With increased focus on our environmental footprint, Bayly continues to develop its capabilities in this area, developing its relationship with the The Natural Step organisation and deepening our understanding of the best value opportunities that can be achieved for our clients.

Bayly uses a suite of state of the art anaylsis and modelling toolsto reduce project leadtimes and reduce technical risk;

|